Science

DJI Enterprise Unveils New White Paper on Mining Automation

DJI Enterprise has released a new white paper detailing the automation of mining workflows through its DJI Dock system. The report, titled “Implementing an Automated Mining Workflow using DJI Dock: A Guide for Successfully Integrating the DJI Dock into Your Mining Operations,” provides insights for commercial mining leaders on transitioning from manual drone operations to an automated drone program designed for BVLOS (Beyond Visual Line of Sight) missions.

This white paper highlights the significant potential of automating mining workflows. By adopting these technologies, mining operations can conduct more frequent inspections, enhance decision-making processes, standardize data capture and reporting, and ultimately improve worker safety and efficiency across various sites, including pits, processing plants, and infrastructure.

Transforming Mining Operations with Automation

The global mining industry represents a substantial economic force, reporting revenues exceeding US$3 trillion in 2023. Automation technologies are rapidly transforming this sector, driving improvements in operational efficiency, safety, and sustainability. The white paper outlines a comprehensive approach for implementing an end-to-end automated mining workflow using DJI’s drone-in-box enterprise solution, the DJI Dock, alongside its flight control software, FlightHub 2.

By employing the DJI Dock for automated mining workflows, operations can see notable increases in productivity compared to traditional manual drone flights and data processing. This boost in efficiency largely stems from eliminating the need for on-site staffing of drone pilots and the time-consuming processes associated with photogrammetry. Notably, tests revealed that the time required to conduct a post-blast photogrammetry survey dropped from 1.2 hours to just 30 minutes. A single DJI Dock allows remote pilots to conduct approximately 150-200 flights monthly, equating to up to 50 flight hours.

Enhancing Safety and Efficiency

Mining sites are inherently dangerous, characterized by heavy machinery, open pits, and blasting activities. Automation allows operators to perform inspections from a Remote Operations Center (ROC), distancing them from hazardous environments. This enables quicker analysis of blast movements, ensuring safer operations. The ability to conduct repeatable surveys and inspections more frequently enhances asset management and compliance with environmental regulations.

The white paper features two case studies from Australia that showcase effective implementation of automated mining workflows. At Rio Tinto’s Gudai-Darri iron ore mine in the Pilbara region, automated drone operations demonstrated resilience in extreme weather conditions, contributing to improved safety and operational efficiency. Remote monitoring and automatic recharging facilitated data-driven decision-making.

At the Paddington Operations in Kalgoorlie, the DJI Dock was utilized for aerial surveys of post-blast muckpiles. With artificial intelligence-driven modeling, operators enhanced grade control, reduced ore dilution, and decreased processing costs by directing higher-quality ore to the processing plant.

The insights provided in this white paper serve as a valuable resource for mining companies looking to embrace automation and realize the associated benefits. For those interested, the full white paper can be downloaded from DJI Enterprise’s official website.

-

Business5 months ago

Business5 months agoKenvue Dismisses CEO Thibaut Mongon as Strategic Review Advances

-

Lifestyle5 months ago

Lifestyle5 months agoHumanism Camp Engages 250 Youths in Summer Fest 2025

-

Sports5 months ago

Sports5 months agoDe Minaur Triumphs at Washington Open After Thrilling Comeback

-

Sports5 months ago

Sports5 months agoTupou and Daugunu Join First Nations Squad for Lions Clash

-

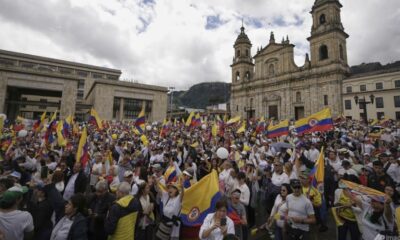

Top Stories5 months ago

Top Stories5 months agoColombian Senator Miguel Uribe Shows Signs of Recovery After Attack

-

Health5 months ago

Health5 months agoNew Study Challenges Assumptions About Aging and Inflammation

-

World5 months ago

World5 months agoASEAN Gears Up for Historic Joint Meeting of Foreign and Economic Ministers

-

World3 months ago

World3 months agoSouth Korea’s Foreign Minister Cho Hyun to Visit China This Week

-

Business5 months ago

Business5 months agoOil Prices Surge Following New EU Sanctions on Russia

-

Entertainment5 months ago

Entertainment5 months agoDetaşe-Sabah Violin Ensemble Captivates at Gabala Music Festival

-

Business3 months ago

Business3 months agoStarling Bank Plans Secondary Share Sale, Targeting $5.4 Billion Valuation

-

Entertainment5 months ago

Entertainment5 months agoBaku Metro Extends Hours for Justin Timberlake Concert