Science

DJI Enterprise Launches White Paper on Mining Workflow Automation

DJI Enterprise has unveiled a new white paper titled “Implementing an Automated Mining Workflow using DJI Dock,” which provides a comprehensive guide for integrating automated drone operations into commercial mining activities. Released on October 30, 2025, the document aims to assist industry leaders in transitioning from manual drone operations to fully automated systems, particularly for Beyond Visual Line of Sight (BVLOS) missions.

The report highlights the potential benefits of automation in the mining sector, which generated revenues exceeding US$3 trillion in 2023. By optimizing workflows, mining operations can increase inspection frequency, enhance data standardization, and improve both worker safety and operational efficiency across various sites.

Streamlining Mining Operations with Automation

The white paper outlines the process for implementing an end-to-end automated mining workflow using DJI’s drone-in-box solution, the DJI Dock, in conjunction with flight control software known as FlightHub 2. This combination allows for significant productivity gains when compared to traditional manual drone flights.

For instance, tests indicate that the time to conduct a post-blast photogrammetry survey has reduced from 1.2 hours to just 30 minutes. A single DJI Dock can facilitate between 150-200 flights per month, equating to roughly 50 flight hours. Additionally, the use of automated ground control points can result in time savings of up to 94% in data processing.

Enhancing Safety and Efficiency

Mining environments often pose significant hazards due to the presence of heavy machinery, open voids, and blasting activities. By utilizing automated workflows, operators can conduct more frequent inspections from a Remote Operations Center (ROC), minimizing risks associated with close proximity to dangerous areas.

The white paper details how these workflows allow for quicker analysis of blast movements, enabling safer operational restarts. Furthermore, regular surveys can be conducted, ensuring that assets remain in good condition, environmental compliance is maintained after adverse weather events, and infrastructure projects stay on track.

The document also features two case studies from Australian mining operations, demonstrating best practices in automation. At Rio Tinto’s Gudai-Darri iron ore mine, automated drone operations have proven effective even in challenging conditions, including extreme heat and cyclones. This approach not only enhanced safety but also supported data-driven decision-making through remotely monitored flights and automatic recharging.

At the Paddington Operations in Kalgoorlie, the DJI Dock was employed for aerial surveys of post-blast muckpiles. By leveraging AI-driven modeling, operators improved grade control, reduced ore dilution, and lowered processing costs by ensuring that higher-quality ore was directed to processing facilities.

The full white paper is available for download, offering valuable insights for mining companies looking to harness the benefits of automation.

-

Business5 months ago

Business5 months agoKenvue Dismisses CEO Thibaut Mongon as Strategic Review Advances

-

Lifestyle5 months ago

Lifestyle5 months agoHumanism Camp Engages 250 Youths in Summer Fest 2025

-

Sports5 months ago

Sports5 months agoDe Minaur Triumphs at Washington Open After Thrilling Comeback

-

Sports5 months ago

Sports5 months agoTupou and Daugunu Join First Nations Squad for Lions Clash

-

Top Stories5 months ago

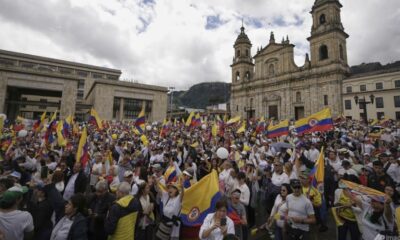

Top Stories5 months agoColombian Senator Miguel Uribe Shows Signs of Recovery After Attack

-

Health5 months ago

Health5 months agoNew Study Challenges Assumptions About Aging and Inflammation

-

World5 months ago

World5 months agoASEAN Gears Up for Historic Joint Meeting of Foreign and Economic Ministers

-

World3 months ago

World3 months agoSouth Korea’s Foreign Minister Cho Hyun to Visit China This Week

-

Business5 months ago

Business5 months agoOil Prices Surge Following New EU Sanctions on Russia

-

Entertainment5 months ago

Entertainment5 months agoDetaşe-Sabah Violin Ensemble Captivates at Gabala Music Festival

-

Business3 months ago

Business3 months agoStarling Bank Plans Secondary Share Sale, Targeting $5.4 Billion Valuation

-

Entertainment5 months ago

Entertainment5 months agoBaku Metro Extends Hours for Justin Timberlake Concert