World

Tesla Mandates Suppliers to Exclude China-Made Parts for US Cars

Tesla has mandated that its suppliers eliminate any components made in China from the production of its vehicles in the United States. This move, reported by the Wall Street Journal on November 14, 2023, reflects the automaker’s ongoing efforts to reduce reliance on Chinese manufacturing amid rising trade tensions and tariffs.

According to sources familiar with the situation, Tesla and its suppliers have already begun replacing certain China-made components and aim to transition all remaining parts to those sourced from other countries within the next year or two. The company has not yet issued a public comment on the report, and Reuters was unable to confirm the details immediately.

This strategic shift comes as Tesla grapples with fluctuating tariffs linked to the ongoing US-China trade dispute, which has complicated pricing strategies for automakers. In light of these challenges, Tesla has been increasing its North American sourcing for its US factories over the past two years, as noted in an April report by Reuters.

Sales of Tesla’s vehicles manufactured in China have also shown signs of decline. Data from the China Passenger Car Association indicated that sales in October 2023 dropped by 9.9 percent compared to the previous year, totaling 61,497 units. This decline reversed a slight increase of 2.8 percent observed in September. Notably, production of the Model 3 and Model Y from Tesla’s Shanghai plant, including exports, fell by 32.3 percent from September 2023.

The broader context involves increasing tensions between the United States and China, which have left automotive executives in a state of uncertainty as they navigate supply chain challenges. The inconsistent tariff policies implemented by former US President Donald Trump and concerns regarding rare earth material bottlenecks and chip shortages have prompted companies to rethink their dependence on Chinese manufacturing.

In a similar move, General Motors recently instructed thousands of its suppliers to eliminate components sourced from China. This trend signals a significant shift in the automotive industry as manufacturers assess their supply chains and mitigate risks associated with geopolitical tensions.

As the situation continues to evolve, Tesla’s decision underscores the urgency for automakers to adapt to changing market dynamics and establish more resilient supply chains. This strategic repositioning may influence not only Tesla’s operations but also set a precedent for other automotive companies navigating similar challenges.

-

Lifestyle4 months ago

Lifestyle4 months agoHumanism Camp Engages 250 Youths in Summer Fest 2025

-

Business4 months ago

Business4 months agoKenvue Dismisses CEO Thibaut Mongon as Strategic Review Advances

-

Sports4 months ago

Sports4 months agoDe Minaur Triumphs at Washington Open After Thrilling Comeback

-

Top Stories4 months ago

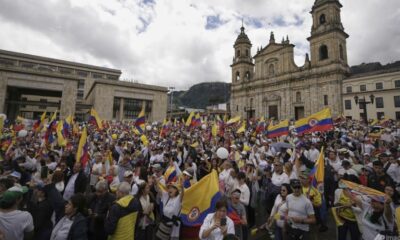

Top Stories4 months agoColombian Senator Miguel Uribe Shows Signs of Recovery After Attack

-

Sports4 months ago

Sports4 months agoTupou and Daugunu Join First Nations Squad for Lions Clash

-

Health4 months ago

Health4 months agoNew Study Challenges Assumptions About Aging and Inflammation

-

World4 months ago

World4 months agoASEAN Gears Up for Historic Joint Meeting of Foreign and Economic Ministers

-

Business4 months ago

Business4 months agoOil Prices Surge Following New EU Sanctions on Russia

-

Entertainment4 months ago

Entertainment4 months agoDetaşe-Sabah Violin Ensemble Captivates at Gabala Music Festival

-

Entertainment4 months ago

Entertainment4 months agoBaku Metro Extends Hours for Justin Timberlake Concert

-

Business4 months ago

Business4 months agoU.S. House Approves Stablecoin Bill, Sends to Trump for Signature

-

Top Stories4 months ago

Top Stories4 months agoRethinking Singapore’s F&B Regulations Amid Business Closures