Science

Mitsubishi Unveils Underwater Robot for Nuclear Reactor Inspections

Mitsubishi Heavy Industries has introduced a new underwater navigation robot designed to inspect nuclear reactor vessels in Japan. Announced on October 10, 2025, this advanced technology aims to enhance safety and efficiency in high-radiation environments, as reported by the Japan Society of Maintenology.

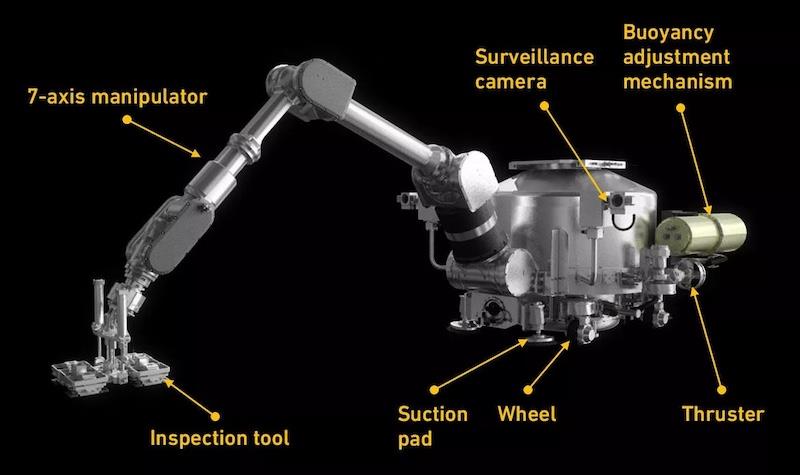

The robot, named the A-UT Machine, is engineered to conduct non-destructive inspections of the weld lines within nuclear reactors. Measuring 1.8 meters in length, 1 meter in width, and 0.9 meters in height, it weighs 400 kilograms when on land, although this weight becomes negligible when submerged in water.

Equipped with thrusters and wheels, the A-UT Machine can navigate along the walls of reactor vessels. Its innovative seven-axis manipulator arm is capable of handling loads up to 10 kilograms with a remarkable positioning accuracy of ±0.1 millimeters. This precision allows the robot to carry out critical inspections efficiently.

Mitsubishi’s developers highlighted that the manipulator features a tool changer at its tip. This enables quick switching of inspection tools, enhancing adaptability during inspections. The A-UT Machine can operate at depths of up to 20 meters, with real-time tracking facilitated by a target mounted on the robot, ensuring precise orientation through triangulation.

The ability to operate two units simultaneously allows for a significant reduction in inspection time, an essential factor in maintaining the safety and functionality of nuclear facilities. Control of the robot is achieved remotely via a desktop computer and joystick, providing operators with effective oversight during inspections.

Since its introduction to pressurised water reactor (PWR) plants in Japan in 1995, the A-UT Machine has been deployed 46 times. Its reliability and effectiveness have led to its recognition as the “#1 Maintenance Heritage” by the Japan Society of Maintenology. This designation acknowledges the robot’s contribution to maintenance technology as part of humanity’s cultural heritage.

In a sector where safety is paramount, the development of the A-UT Machine represents a significant advancement in the inspection capabilities of nuclear reactors. As the technology continues to evolve, it promises to enhance operational safety and efficiency in Japan’s nuclear energy sector.

-

World5 months ago

World5 months agoSouth Korea’s Foreign Minister Cho Hyun to Visit China This Week

-

Business5 months ago

Business5 months agoStarling Bank Plans Secondary Share Sale, Targeting $5.4 Billion Valuation

-

Top Stories5 months ago

Top Stories5 months agoMunsang College Celebrates 100 Years with Grand Ceremony

-

World5 months ago

World5 months agoPAS Aims to Expand Parliamentary Influence in Upcoming Election

-

Business7 months ago

Business7 months agoKenvue Dismisses CEO Thibaut Mongon as Strategic Review Advances

-

Lifestyle6 months ago

Lifestyle6 months agoHumanism Camp Engages 250 Youths in Summer Fest 2025

-

Sports6 months ago

Sports6 months agoDe Minaur Triumphs at Washington Open After Thrilling Comeback

-

Sports7 months ago

Sports7 months agoTupou and Daugunu Join First Nations Squad for Lions Clash

-

Top Stories7 months ago

Top Stories7 months agoColombian Senator Miguel Uribe Shows Signs of Recovery After Attack

-

World7 months ago

World7 months agoASEAN Gears Up for Historic Joint Meeting of Foreign and Economic Ministers

-

Health6 months ago

Health6 months agoNew Study Challenges Assumptions About Aging and Inflammation

-

Business7 months ago

Business7 months agoOil Prices Surge Following New EU Sanctions on Russia