Science

Mitsubishi Unveils Underwater Robot for Nuclear Reactor Inspections

Mitsubishi Heavy Industries has introduced a cutting-edge underwater navigation robot designed for non-destructive inspections of nuclear reactor vessels, particularly in high-radiation environments. This development was reported on October 10, 2025, by the Japan Society of Maintenology. The robot, named the A-UT Machine, is expected to enhance safety and efficiency in inspections at nuclear facilities across Japan.

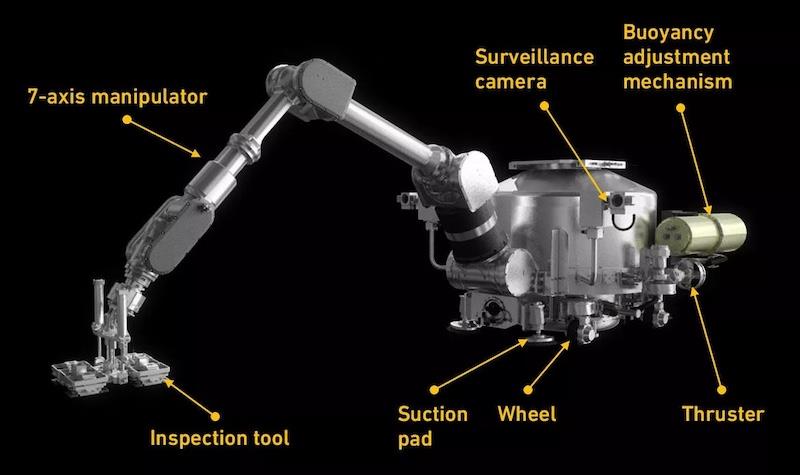

The A-UT Machine measures 1.8 metres in length, 1 metre in width, and 0.9 metres in height, weighing 400 kilograms. When submerged, its weight effectively becomes zero, allowing for easier maneuverability. The robot employs a combination of thrusters and wheels, enabling it to traverse wall surfaces within reactor vessels.

Equipped with a seven-axis manipulator arm, the robot can perform precise weld-line inspections with a load capacity of up to 10 kilograms and positioning accuracy of ±0.1 millimetres. The arm features a tool changer at its tip, allowing for the quick interchange of inspection tools. This flexibility enables the A-UT Machine to adapt to various inspection requirements efficiently.

Advanced Navigation and Real-Time Tracking

The robot is designed to operate at depths of up to 20 metres, making it suitable for most reactor vessel environments. Its position is monitored in real time through a target mounted on the device, utilizing triangulation techniques to maintain accurate orientation. Mitsubishi developers highlighted that the simultaneous operation of two units can significantly reduce inspection time, enhancing overall productivity in maintenance tasks.

Control of the A-UT Machine is conducted remotely via a desktop computer and joystick, allowing operators to manage inspections from a safe distance. This system has been in active service at pressurized water reactor (PWR) plants in Japan since 1995, with a total of 46 deployments recorded to date.

The Japan Society of Maintenology has recognized the A-UT Machine as the “#1 Maintenance Heritage,” a designation that underscores its significance in maintenance technology and its contribution to cultural heritage. This certification reflects the robot’s role in advancing safety protocols in nuclear facilities, an area of critical importance to public safety and environmental security.

Mitsubishi’s innovation in the field of underwater robotics not only showcases technological advancement but also reinforces the commitment to maintaining safety standards within the nuclear industry. As the demand for efficient and effective inspection methods grows, the A-UT Machine stands out as a pivotal development in ensuring the integrity of nuclear reactor vessels.

-

Business5 months ago

Business5 months agoKenvue Dismisses CEO Thibaut Mongon as Strategic Review Advances

-

Lifestyle4 months ago

Lifestyle4 months agoHumanism Camp Engages 250 Youths in Summer Fest 2025

-

Sports4 months ago

Sports4 months agoDe Minaur Triumphs at Washington Open After Thrilling Comeback

-

Sports5 months ago

Sports5 months agoTupou and Daugunu Join First Nations Squad for Lions Clash

-

Top Stories5 months ago

Top Stories5 months agoColombian Senator Miguel Uribe Shows Signs of Recovery After Attack

-

World5 months ago

World5 months agoASEAN Gears Up for Historic Joint Meeting of Foreign and Economic Ministers

-

Health4 months ago

Health4 months agoNew Study Challenges Assumptions About Aging and Inflammation

-

Business5 months ago

Business5 months agoOil Prices Surge Following New EU Sanctions on Russia

-

Entertainment4 months ago

Entertainment4 months agoDetaşe-Sabah Violin Ensemble Captivates at Gabala Music Festival

-

Entertainment4 months ago

Entertainment4 months agoBaku Metro Extends Hours for Justin Timberlake Concert

-

Top Stories5 months ago

Top Stories5 months agoRethinking Singapore’s F&B Regulations Amid Business Closures

-

Business5 months ago

Business5 months agoU.S. House Approves Stablecoin Bill, Sends to Trump for Signature