Science

Mitsubishi Develops Underwater Robot for Nuclear Inspections

Mitsubishi Heavy Industries has unveiled a cutting-edge underwater navigation robot designed for non-destructive inspections of nuclear reactor vessels in Japan. Announced on October 10, 2025, the innovation aims to enhance safety and efficiency in high-radiation environments, as detailed by the Japan Society of Maintenology.

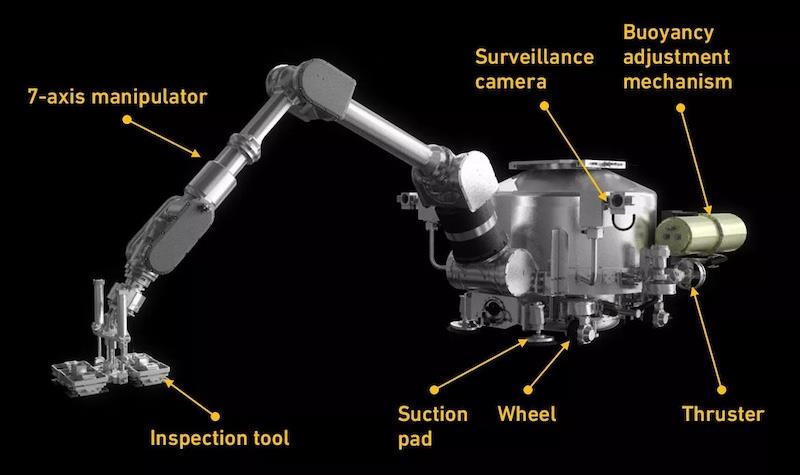

The newly developed unit, named the A-UT Machine, is engineered to operate underwater, performing detailed weld-line inspections using its advanced manipulator arm. Measuring 1.8 metres in length, 1 metre in width, and 0.9 metres in height, the robot weighs 400 kilograms, although it becomes weightless when submerged. Its mobility is facilitated by a combination of thrusters and wheels, allowing it to traverse along wall surfaces effectively.

The manipulator arm of the A-UT Machine boasts a design with seven axes, enabling it to carry a load of up to 10 kilograms with positioning precision of ±0.1 millimetres. “The manipulator features a tool changer at the tip, allowing for easy swapping of inspection tools,” the developers noted, highlighting the unit’s versatility in various inspection scenarios.

Operational Capabilities and Efficiency

Designed for depths of up to 20 metres, the robot’s real-time positioning is tracked via a target mounted on the unit, employing triangulation to ensure accurate orientation. The developers emphasized that the simultaneous operation of two A-UT Machines significantly reduces inspection time, enhancing efficiency in critical maintenance tasks.

Control of the robot is managed remotely through a desktop computer and joystick, simplifying operations for technicians. Since its introduction, the system has been utilized in pressurised water reactor (PWR) plants across Japan since 1995, with a total of 46 deployments recorded to date.

The A-UT Machine has received recognition as the #1 Maintenance Heritage by the Japan Society of Maintenology. The society characterizes Maintenance Heritage as a “historic heritage related to maintenance technology also constituting a cultural heritage of humankind,” underscoring the significance of this technological advancement.

As nuclear safety remains a paramount concern, the deployment of such innovative technologies as the A-UT Machine represents a proactive step toward ensuring the integrity of critical infrastructure while safeguarding human operators from hazardous environments.

-

World5 months ago

World5 months agoSouth Korea’s Foreign Minister Cho Hyun to Visit China This Week

-

Business5 months ago

Business5 months agoStarling Bank Plans Secondary Share Sale, Targeting $5.4 Billion Valuation

-

Top Stories5 months ago

Top Stories5 months agoMunsang College Celebrates 100 Years with Grand Ceremony

-

World5 months ago

World5 months agoPAS Aims to Expand Parliamentary Influence in Upcoming Election

-

Business7 months ago

Business7 months agoKenvue Dismisses CEO Thibaut Mongon as Strategic Review Advances

-

Lifestyle6 months ago

Lifestyle6 months agoHumanism Camp Engages 250 Youths in Summer Fest 2025

-

Sports6 months ago

Sports6 months agoDe Minaur Triumphs at Washington Open After Thrilling Comeback

-

Sports7 months ago

Sports7 months agoTupou and Daugunu Join First Nations Squad for Lions Clash

-

Top Stories7 months ago

Top Stories7 months agoColombian Senator Miguel Uribe Shows Signs of Recovery After Attack

-

World7 months ago

World7 months agoASEAN Gears Up for Historic Joint Meeting of Foreign and Economic Ministers

-

Health6 months ago

Health6 months agoNew Study Challenges Assumptions About Aging and Inflammation

-

Business7 months ago

Business7 months agoOil Prices Surge Following New EU Sanctions on Russia